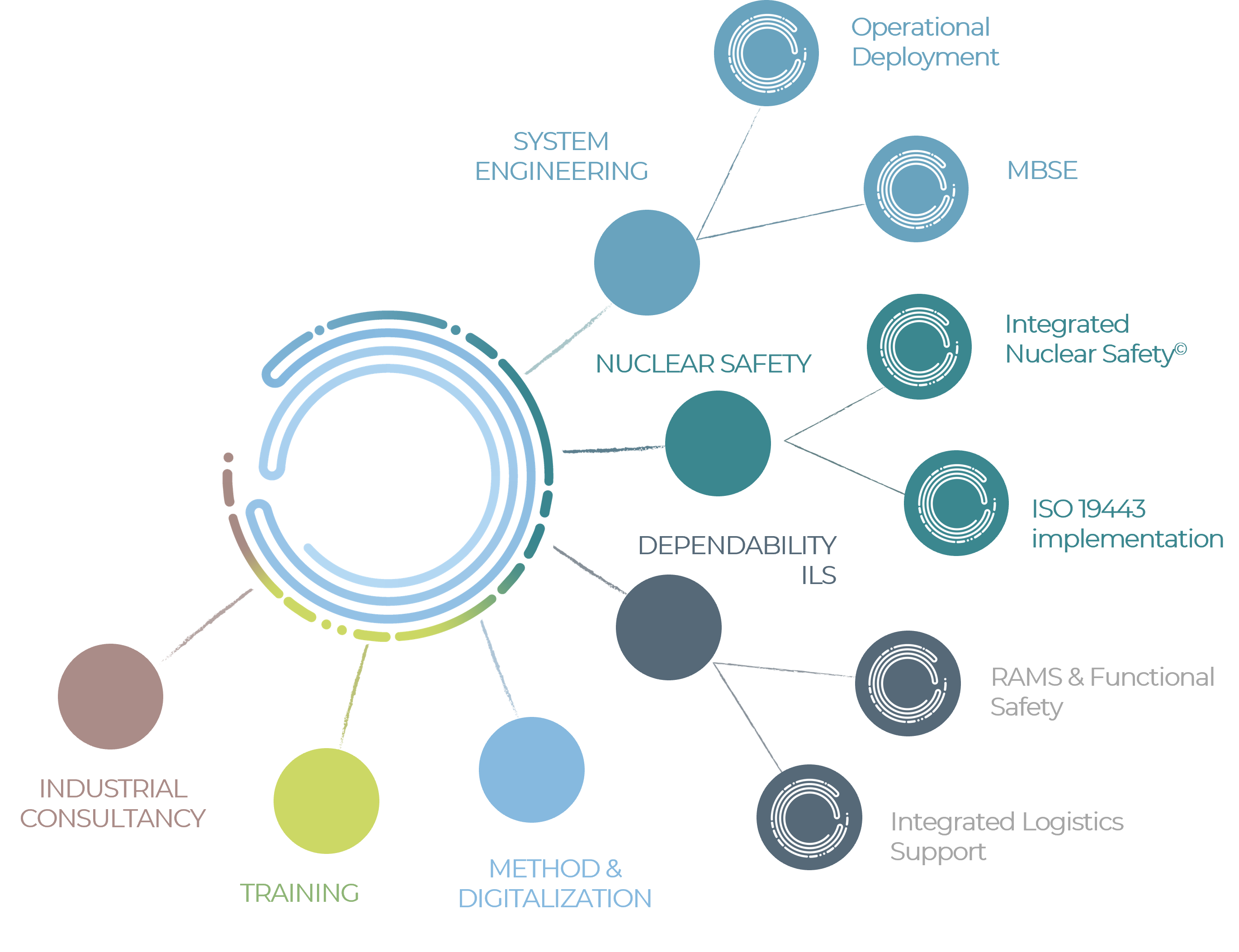

OFFER

IT IS DIFFICULT TO ILLUSTRATE OUR KNOW-HOW WITHOUT MAKING TONS OF IT.

Here is AXONE Engineering offer, quite simply.

If you want to know more, you can scroll down. That said, if you really want to discover AXONE, there is nothing better than an exchange because if you are interested in us, it is obvious that we will want to know more about you.

1.

System Engineering

ENCOURAGE AUTONOMY

Since we are not omniscient and each of us holds a part of the global knowledge, we must make room for autonomy, not dependance.

SHARE THE PROCESS

We must give meaning to the process in order to unite people. To do this, we must demonstrate and communicate.

MAKE THE APPROACH ACCESSIBLE

The methodological approach must be de-sacralized by making it applicable, by explaining to the stakeholders the benefits they will get from it.

RELY ON THE METHODS

System Engineering standards exist, why would you ignore them?

BE PRAGMATIC

Standards are only useful if they are applicable. Each project is different and the challenge is to adapt the standard while avoiding any additional constraint.

AXONE placed System Engineering at the heart of the operations and applies these core values to its corporate culture, customer relations and partnerships.

When dealing with large and complex projects, an accurate design approach must meet 3 main criteria:

• Functionally respond to the need (ability to be exploited),

• Meet the standard and prescriptive requirements,

• Financially respect the budget constraints, regarding the overall ownership cost.

If we place System Engineering at the heart of the design approach from the conceptualization phase, we bet that risk management can become global.

That said, adopting a design approach based on System Engineering guidelines does not make AXONE any different from other service companies. What makes us different is the applied and pragmatic nature of our approach. Our System culture is based on the engineering of interdisciplinary performances such as Nuclear Safety, Dependability and Integrated Logistics Support. Too often neglected compared to Engineering, and called “Constraint Functions”, these disciplines share the same backbone as System Engineering, roughly through Requirements Engineering.

This cross-disciplinary vision requires to have a great list of technical qualifications but above all to be open-minded and skilled in several fields to build a common “federating” vocabulary and overcome complexity.

2.

Nuclear Safety

DURING FEASIBILITY STUDIES

To identify the safety requirements in advance, for each lifecycle phases of the installation.

AT THE DESIGN STAGE

To contribute to the definition of the technical solution, to provide demonstrations and to anticipate the required recordings during the manufacturing phase.

DURING MANUFACTURING, REALIZATION AND QUALIFICATION

To follow the execution actions, check the records and verify compliance with the requirements.

DURING MAINTENANCE AND MONITORING

To ensure compliance with requirements in the long run, anticipate drifts and assess the impact of the deviations.

IN OPERATION

To assess the impact of modifications on safety requirements and adopt the new regulations.

DURING SHUTDOWN AND DISMANTLING

To optimize technical and regulatory choices, and to consider waste management channels as a whole.

Any system must meet a certain number of constraints to be sure of functioning, especially in a nuclear context.

Nuclear Safety, as a constraint function of the system, must be integrated into all activities related to the installation, interfacing with all disciplines in order to optimize the whole.

Within the framework of a product, everything must be designed so that it can meet the functional constraints that will ensure safety in the nuclear subsystem or full system.

Safety must be controlled throughout the system or installation lifecycle, from feasibility studies to dismantling, including operation and monitoring.

For all these reasons, AXONE considers Integrated Nuclear Safety © as the most efficient approach, as an original method to meet the requirements and expectations of the QA 84 and the decree of February 7, 2012.

3.

Dependability

IN OPERATION

To analyze technical facts, capitalize on the information and better take it into account for the future developments

AT THE DEVELOPMENT STAGE

To identify the risks, the means to control them and demonstrate their control and evaluation

IN PREPARATION FOR OPERATION

To anticipate maintenance operations and ensure the availability of installations or products

DURING VERIFICATION OR VALIDATION TESTS

To develop test plans, monitoring and analysis tests, for the demonstration of Dependability

At AXONE, we consider that Dependability supports all the System Engineering processes. We see it as a specialty just like Nuclear Safety.

With Dependability, the approach remains systemic while providing input data and going down to the levels of subsystems, equipment and products. Closer to the disciplines, it tends to master a sub-system by taking into account mechanical, electronic or computer problems, even in a common set that must be integrated. The System culture becomes once again very important in the approach.

AXONE has come to the System approach through Dependability. Aware that some of the problems encountered in the Dependability studies could have been solved in advance, by a more comprehensive functional approach, we have done something quite the contrary. We wanted a pragmatic approach that could comply with an industrial prescriptive approach as well as with a short cycle on some projects to gain in reactivity and agility.

4.

Consulting

We say yes to consultancy but only to transform things for good.

Once the project has been clarified, the strategies defined and the objectives set, you need a “system” to get things done. This requires an accurate and simple communication, user-friendly

processes, right functions to “get things done” in the organization and the talent of the people who will carry out the project.

Even the greatest ideas never come to fruition without a vision of “how it’s going to work”.

We accompany our customers towards an operational reality that will ensure their performance. And if our customers are willing to adopt a responsible approach to the preservation of the living world, we’ll undoubtedly be even more different from our competitors, because the AXONE Group has written the preservation of the living world into its legal forms.

5.

Training

Design your knowledge and make it a know-how.

The way we engineer Training allows us to design pragmatic and very applied courses.

6.

METHODOLOGIES & DIGITIZATION – TOOLS

Without common and shared methods, business and project processes are carried out blindly: without systematic and structured approaches to solve the technical and scientific challenges which the processes must respond to, no collective progress is possible, and projects cannot meet their objectives over the long run.

Tools and digitization support methods to make them efficient and promote collaborative working, the circulation and sharing of coherent information within teams, facilitate the feedback of indicators, etc. They enable processes to be optimized and support engineering methods.

At AXONE, we believe and have demonstrated, through the deployment of our skills in numerous projects, that it is the coherent consideration of the 3 pillars, Processes, Methods and Tools, in this order, that leads to the performance of projects and organizations and to long-term success.

Deprived of methodological meaning, or too far removed from the company’s know-how and its processes, the information entered into the tools is considered useless and a waste of time by the teams, and loses its reliability in relation to the objectives pursued by the company or the project.

Conversely, failure to take advantage of the technological advances offered by digitalization and the tools available scleroses efficiency through manual, repetitive work, potentially losing a competitive edge in highly competitive markets.

Drawing on our experience in numerous projects over several years with dozens of customers, we have developed tried-and-tested methods for defining and then driving change on these 3 pillars, and anchoring it within teams. This know-how is applied simultaneously to the process, methods and tools pillars, around a shared objective within the teams, and focuses on the definition of “quick-wins”, to gradually get the teams on board and ensure that they can continue the effort over the long term, each at their own level, according to their responsibilities and the project or organizational context.